Transforming organisational delivery performance through an end-to-end mindset

Is’s obvious to say, but in order to regularly deliver small or large change, organisations require several functions and stakeholders to work together. In practice however, most organisations change processes are burdened by excessive organisational friction. Moving ideas through design, build, test and release can feel like being trapped in a game of snakes and ladders. This impacts speed, competitiveness, productivity, and staff morale.

Based on our experience working with large and complex organisations, we see a big benefit in aligning organisations around end-to-end change processes and outcomes.

Shining a light on end-to-end change friction

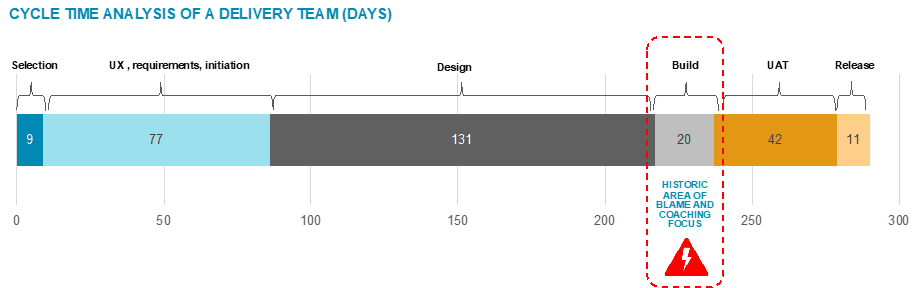

A retailer wanted to investigate their lengthy delivery of regular digital and technology product changes. To do so, we mapped out the time it took, on average, to move a change from ideation to release (this is called flow or cycle time) and found it took around 290 days. See figure 1 for our analysis of the process.

Figure 1. End-to-end value stream analysis of a change process in a retailer

Throughout these 290 days, multiple teams were involved from marketing to customer experience, data, analytics, and software development but the team responsible for building functionality (software development) was often blamed for delays. As such, coaching and process improvement initiatives had historically been focused there.

We found that other product teams across the organisation had similar stories. These inefficient end-to-end change processes impacted the organisation’s competitiveness as well as its top and bottom-line performance. Additionally, staff morale was low across all teams involved.

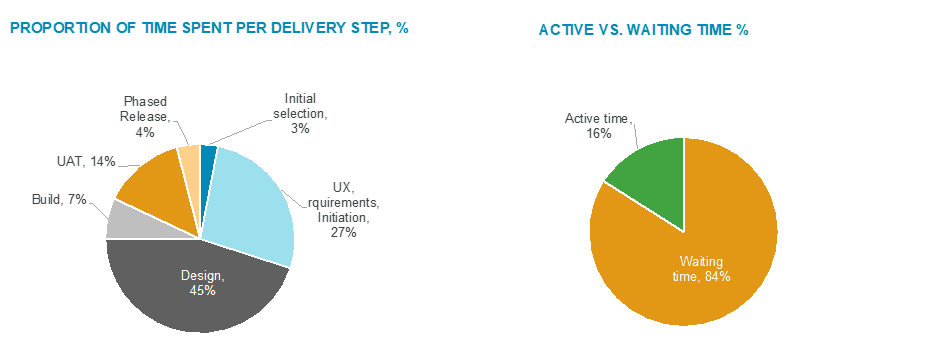

Our analysis showed that 80% of delays could be attributed to designing and planning which together took 200 days. And, while the teams responsible for building products were often blamed for delays, only 7%, or 20 days of the project elapsed during their work. Interestingly, User Acceptance Testing (UAT) took over twice as long totalling 42 days. Finally, a whopping 84% of the total time was lost to waiting.

Figure 2. Analysis of time spent on each activity across the end-to-end delivery process

To fill gaps while waiting, teams took on additional work. While this kept the teams busy, by increasing work-in-progress (WIP), the problems and bottlenecks causing delays in the first place became hidden as work piled up throughout the end-to-end process.

Unfortunately, this is a common occurrence in many organisations. So, why was this happening?

Analysing the root causes:

It was identified there were five main root causes to our client’s inefficient end-to-end process:

- No metrics: No end-to-end operational metrics for leaders and teams to understand end-to-end performance, progress or where bottlenecks lie

- Lack of end-to-end ownership: No individual accountability for end-to-end process performance monitoring and improvement

- Siloes: Siloed organisation structure where each business area was acting in the best interest of their own remit, rather than the best interest of the customer and organisation

- Little cross-silo coordination: Teams not planning and working together, resulting in mis-aligned expectations and a lack of common understanding

- Lack of leadership: Lack of leadership understanding of the problem and support for addressing it.

Optimising the end-to-end process

We applied a seven-step approach to transform the end-to-end change process for the retailer:

- Diagnostic: Analysed a small selection of teams to understand operational performance and used the results with key stakeholders to support the cause for change

- Leadership mobilisation: Engaged with the leadership group (who operated across the siloes) on the benefits case for improved end-to-end management and gained their support to run a pilot to improve two use cases

- Establish end-to-end owners: Agreed the end-to-end owners of processes’ performance (such as Engineering Leads) who enabled continual performance improvement of the process as well as agreed the end-to-end owners of the products (Product Owners)

- Delivery team mobilisation: Shared the initial findings, the case for change, good practice for metric management and agreed what can be done to address the key identified challenges

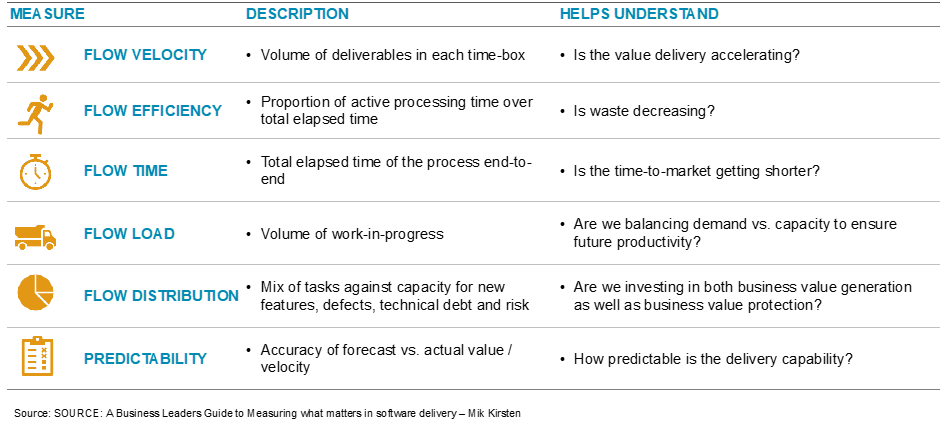

- Performance measurement: Worked with the teams to define what operational metrics should be used to monitor end-to-end performance and how the data will be captured and reported – see figure 3 for example metrics

- Established data-driven retrospectives: Established retrospectives where the end-to-end owners and the teams reviewed the data to identify what was working and what could be improved

- Embedded an end-to-end continuous improvement approach with the product teams: Built, prioritised and established the management of the process improvement backlog, incorporating this effort into the team’s available capacity.

Figure 3. Example metrics to measure end-to-end health and performance

So, what happened to the team?

By implementing the above steps, the organisation saw significant improvements over the following six-month period, including:

- Flow time reduction of 30%

- Reduction in flow load (WIP) of 20%

- Minimum flow efficiency of 50%

- Improved delivery forecast accuracy from 30% to 80%

Additionally, employee engagement levels improved by 20% within the same six months as teams enjoyed being able to make a real difference. Business leaders were happy as teams were operating more successfully and were meeting stakeholder expectations.

In conclusion

Our research shows there is a significant reward for organisations who can optimise their end-to-end change processes. Those organisations who enable cross functional teams, experiment with and support leadership pilots, and who apply a similar approach to the one we highlighted can deliver significant transformations to organisational performance at rapid pace.